We’d like to give special thanks to Bill Spohn with TruTech Tools for inspiring this article. Bill gave an excellent presentation on airflow to industry educators, and we draw on his work in this piece. Bill has worked with Kalos President Bryan Orr to create free educational materials for technicians worldwide.

We throw the term “airflow” around a lot in the A/C industry. It sounds like a simple topic; you measure how well air flows through your system.

But when you think about how an A/C system works and interacts with your home, airflow can get a bit complicated. Are we talking about the blower fan speed? How about the air volume exiting the supply duct and entering the conditioned spaces of the home? Where does the velocity of the air moving through the ducts come in?

You can see that airflow is a deceptively tricky topic. As technicians, we understand it to be a measure of an A/C system’s ability to function properly within a structure, and we approach the subject holistically. As such, we use a few different types of metrics and tools for measuring airflow. This article will only scratch the surface of airflow, how we measure it, and its effects on comfort.

Table of Contents

THREE AIRFLOW TYPES

First of all, we need to dispel the idea that “airflow” refers to one measurement or value. There are actually three types that we can measure: system, supply/return, and mechanical ventilation.

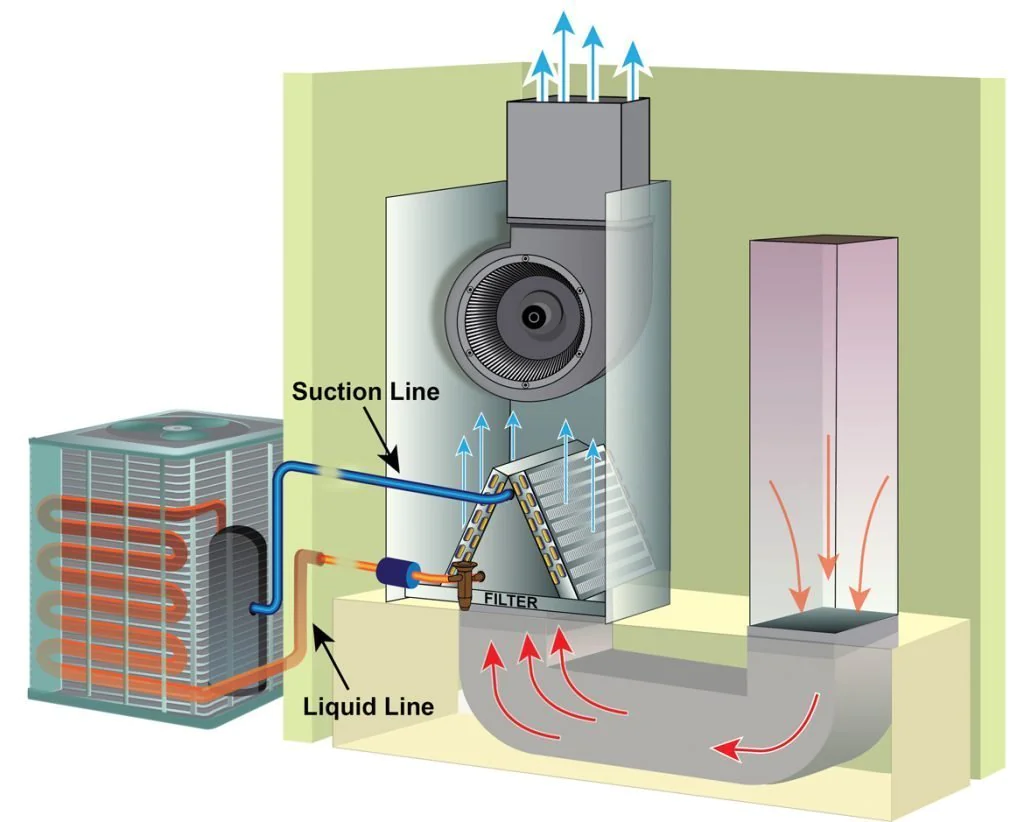

The first type, system airflow, refers to the immediate flow of air in the HVAC equipment. A/C units work because they exchange heat between the home, refrigerant (“Freon”), and outdoors. That heat exchange occurs in two components, each with fans that move air: the evaporator (indoor air handler) and condenser (outdoor unit). The refrigerant inside the evaporator absorbs heat from inside your home as air blows over the coil. The A/C unit then compresses that refrigerant and sends it to the outdoor condenser, where a fan blows over the coils and rejects that heat from the refrigerant to the outdoors.

The second type, supply/return airflow, refers to the flow of air entering and leaving the duct systems in the home. The supply duct brings conditioned air to the home by moving that air away from the air handler. The return duct takes in warm, moist air and moves it to the air handler for conditioning and moisture removal.

The final type, mechanical ventilation, refers to the fresh air intake. Fresh air intake may refer to economizers or makeup air units in the commercial sphere. In residential A/C units, fresh air intake may result from mechanical efforts to remove undesirable air from a space. These efforts include using bathroom exhaust vents and exhaust hoods in the kitchen. When you attempt to reject that air, the house naturally pulls fresh air through open windows, cracks, and other openings.

MEASUREMENTS: UNITS, TOOLS, AND METHODS

We use a few different units for measuring airflow. Some of these units directly measure the air volume moved over a period. Others measure conditions that can tell us a bit more about a system’s airflow.

We primarily measure air volume in cubic feet per minute (CFM). The CFM reading tells us how effectively your unit moves quantities of air through the ducts. We also sometimes measure air velocity, which is the speed at which air travels through the ducts. The speed at which air travels through the ductwork can impact CFM, but it also impacts other comfort concerns, such as duct noise and room temperature control. Air velocity also affects static pressure in the ducts.

Static pressure is one of our most important values when we measure airflow. The ductwork provides resistance to airflow, and static pressure is the pressure exerted on the ductwork by the air. We measure that static pressure with these tools called static pressure tips, and we hook them up to a manometer that displays the data.

Nowadays, technicians have access to a tool called a “TrueFlow Grid” that measures CFM directly. That grid also measures static pressure and pressure drops across the filter and coil. When technicians use one of these grids, they stick it where the filter usually goes, and it reports its readings to the technician’s smartphone via Bluetooth.

However, HVAC technicians can also perform more comprehensive tests that measure the whole home’s air pressure and leakage. One of these cases is when we perform a blower door test. In a blower door test, techs use a blower door to bring down the pressure in a house, and they use a manometer to measure pressure (typically in pounds per square inch or PSI). In doing so, the techs can get an idea of a home’s airtightness, which affects airflow. Air distribution and duct leakage also impact airflow and require pressure readings from manometers.

WHAT DOES MY AIRFLOW INDICATE?

When we measure airflow, our main goal is to look for restrictions. If the airflow is low or appears to be impeded by something, your comfort and your HVAC system’s lifespan and efficiency will suffer.

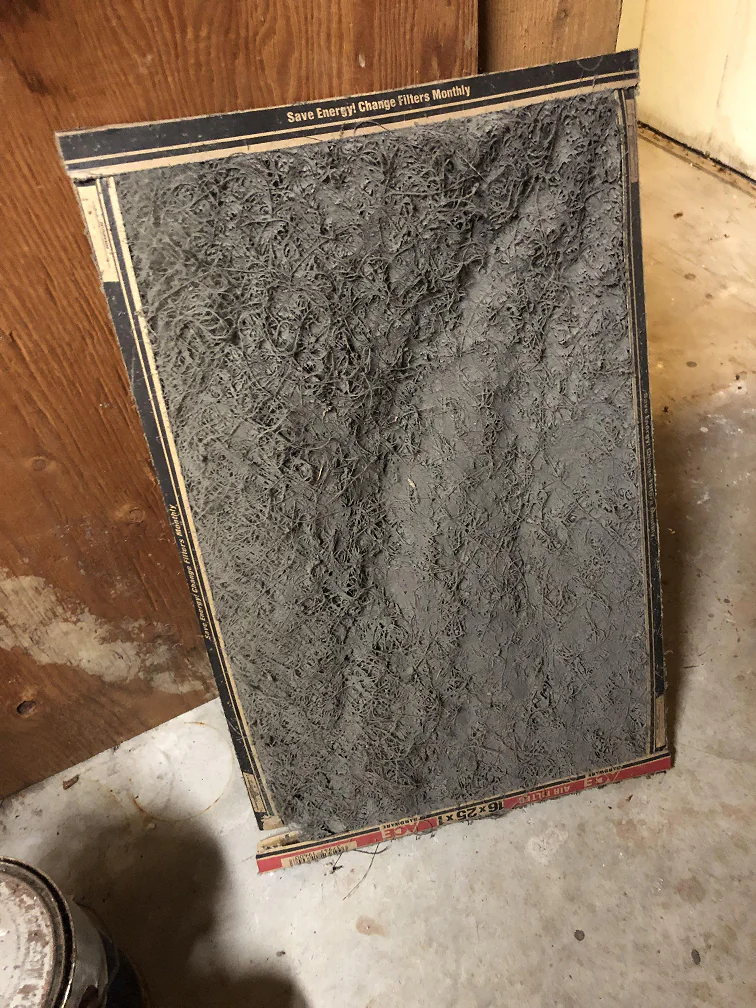

Several conditions may reduce airflow. Some of those conditions are easy to fix, and others are more complicated. The easiest fix is when your airflow is low because of a dirty filter. You can avoid that issue by replacing your air filter monthly whenever you get your power bill. (Of course, we recommend more frequent filter changes if you have pets and plants.) Debris near the outdoor unit is another common but easily fixable issue. You may also have recently had an oak tree shed lots of leaves right by your outdoor unit, obstructing it. In that case, you can remove the debris and see if the airflow improves.

However, the answer is not always that simple. In some cases, your A/C system may have fundamental design flaws that need to be addressed and rectified by a professional. For example, your outdoor unit may not have enough clearance between it and a wall or a garden. It becomes very difficult for the outdoor unit to blow hot air away if it’s blocked on one or multiple sides. In other cases, your ductwork may be leaky, collapsed, or disconnected. In some cases, you may not have enough return air vents in your home, or your ductwork may be oversized. When those are possible causes, it is best to call a technician to assess the A/C system and discuss possible solutions to fix your airflow.